Anodising guide - 2. Basics

|

|

2.1 Properties of the layer

Polished aluminum oxidizes in air very quickly but becomes covered with an air-impermeable

colorless oxide (Al2O3). This very thin (typically 0.5-1 micron thick) layer protects the metal from

further attacks of atmospheric oxygen. It is quite soft and unsightly and isn't acceptable for more advanced

requirements because of its very low strength. However, using an aqueous electrolyte you can build up this

layer much more giving it the following features:

- Hardness: Mohs hardness of about 9 (corundum), quartz has hardness 7, diamond has hardness 10

- Thickness: depending on voltage, anodising duration and other parameters - 5-250 microns (0.005-0.25 mm)

- Dielectric strength: about 30 volts per micron

- Color: colorless to grayish/blackish (depending on the alloy), with suitable metallic alloys the metallic

look of the underlying aluminum is preserved - even at a later coloring.

- Light-resistant and insensitive to scratches. Possible combinations of dyes allow to create almost any

desired color.

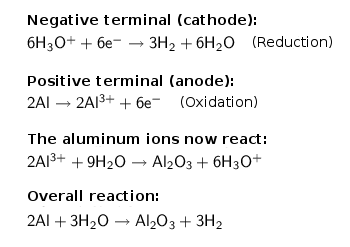

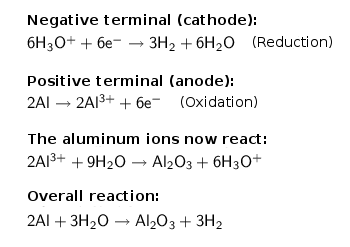

2.2 Chemical reaction

The following main chemical reactions are running in the anodising bath:

There are two things apparent:

- The formation of the layer itself do not consume sulfuric acid. It serves as the electrolyte (this

massively reduces the electrical resistance of the bath) and - this is the important part - to solve the

layer locally, thus ensuring a continuous current flow and building of layer structure. Due to the small layer

thickness a refreshing of sulfuric acid (recovery of initial concentration of 15-20%) is rarely necessary.

- At the cathode (negative terminal) gaseous hydrogen is generated, which in large quantities should be removed

because of the explosion risk (hydrogen is odorless, tasteless and colorless!).

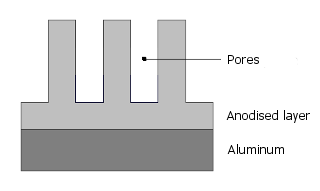

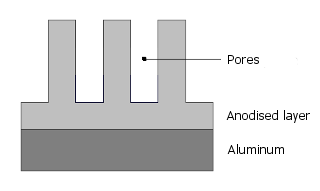

2.3 Structure of the layer

First in sulfuric acid a closed layer is electrolytically produced which grows further to fine capillary pores:

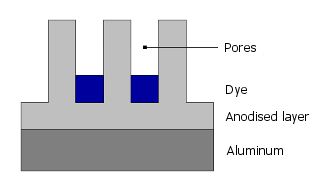

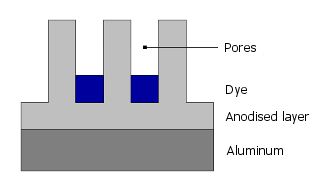

The dye molecules now migrate into these pores:

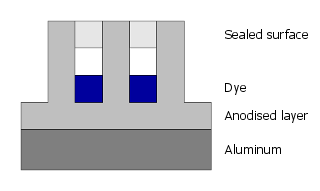

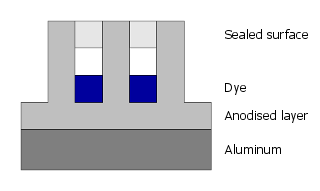

Finally, the pores are closed by sealing.

So the dye is not applied on but is part of the anodized layer itself and thus protected very well from abrasion

and chemical attack.